Views: 0 Author: Site Editor Publish Time: 2025-08-04 Origin: Site

A brass valve helps control how liquids or gases move in a system. It is made from a strong mix of copper and zinc. To pick the right brass valve, you need to know about its features. These include size, pressure rating, and connection type. These features change how well the system works and how safe it is. This is important in plumbing or factories.

Feature Aspect | Impact on Selection |

|---|---|

Valve Size | Makes sure the flow is right and fits the system |

Pressure Ratings | Stops the valve from breaking and keeps it safe |

Temperature Ratings | Helps the valve last long and work well in different conditions |

Connection Types | Makes it easy to connect with brass fittings or quick connect couplings |

Brass valves are very strong and do not rust easily. This is why people like to use them for tough jobs.

Brass valves help control how liquids and gases move. They are made from copper and zinc, which makes them strong. This material does not rust and lasts a long time.

Important features are size, pressure rating, temperature limit, and connection type. These features help you choose the right valve. The right valve keeps systems safe and working well.

Brass valves are simple to shape and easy to put in. This makes them cheap and good for plumbing, heating, and factories.

There are different types like ball, check, gate, and globe valves. Each type is made for a special job in homes or factories.

Brass valves fit well with brass fittings and quick connect couplings. This helps stop leaks and makes strong, safe connections.

A brass valve is a device made from copper and zinc. It is important in many plumbing and piping systems. Some rules, like EN331:2015 and ASME B16.34, say brass valves help control liquids or gases. You can find these valves in homes, businesses, and factories. The material makes the brass valve strong, easy to shape, and not too expensive.

There are different types of brass valves, like ball valves, check valves, and gate valves. Each type has its own way to control flow. A ball valve has a brass ball with a hole that turns to open or close. A check valve lets liquid move one way using a spring or gravity. The main parts, like the body, stem, seats, and seals, work together for good performance. Many systems use brass fittings and quick connect couplings for tight connections.

Note: Brass valves are easy to put in and work with many fluids. They fight germs and move heat well, so they are good for water, gas, and HVAC jobs.

Standard | Origin | Application Field |

|---|---|---|

EN331:2015 | European Union | Gas systems in homes and businesses |

EN13828:2003 | European Union | Heating systems, focusing on heat and pressure |

ASME B16.34 | United States | Factories, like chemical, power, and oil & gas |

API 6D | United States | Oil and gas pipes |

The main job of brass valves is to control flow. These valves can start, stop, or change how fluids move in a system. For example, a brass valve can turn water on or off, slow down gas, or stop backflow. Each valve type is made for a special flow job:

Ball valves shut off or open flow fast with a short turn.

Check valves let fluid go one way and stop it from going back.

Gate valves use a wedge to block or let flow through, which helps in big systems.

Brass valves keep systems safe by stopping dirt and pressure drops. They do not rust and last a long time, even in tough places like HVAC, farms, and factories. Some brass valves, like check valves, work by themselves and need little care.

Brass valves are not too costly and work well for medium pressure and heat. They are great for plumbing, heating, and cooling where good flow control matters. When used with brass fittings or quick connect couplings, they help make strong and leak-free systems.

Brass is used for many valves because it mixes copper and zinc. Makers pick certain brass types for strength, easy shaping, and lasting a long time. The most used brass for valves is alpha-beta brass. It has 55-60% copper and 35-45% zinc. This mix works well for radiator valves, taps, and pipe fittings. The table below shows the usual copper and zinc amounts in brass for valves:

Brass Type | Copper (%) | Zinc (%) | Notes on Use and Properties |

|---|---|---|---|

Alpha-Beta Brass | 55-60 | 35-45 | Used a lot for valves; has good strength, hardness, fights rust, and is easy to shape. |

Alpha Brass | 55-65 | 35-45 | Fights rust and shapes well when cold; used for building and decoration. |

High Zinc Beta | ~15 | ~85 | Used for die casting; flows well and resists wear but not great for valves. |

Brass looks shiny and yellow, which many people like. This color makes brass valves nice for places where you can see them, like fancy plumbing or HVAC parts. Makers sometimes add chrome, nickel, or clear coats to make them look better and last longer.

Brass has many good points for making valves. It does not rust much, so it works well with water and weak chemicals. Brass is softer than stainless steel, so it is easier to cut and shape. This helps lower costs and lets makers build tricky quick connect couplings and brass adapter fittings.

Brass valves are simple to put in and work with soldering, threading, and compression fittings. These things make them good for plumbing, HVAC, and water wells.

Brass also moves heat and electricity well, so it is good for hot water and heating. Some brass has lead, and some does not, so makers can meet safe water rules. Brass does not handle very high heat or strong chemicals as well as stainless steel, but it is still a smart choice for most homes and businesses.

Benefit Category | Brass Valves Characteristics | Comparison to Other Metals/Materials |

|---|---|---|

Durability | Strong enough for most homes and businesses | Lasts longer than plastic and aluminum; not as strong as stainless steel |

Corrosion Resistance | Does not rust much, especially in water and weak chemicals | Better than steel and aluminum in water; not as good as stainless steel |

Temperature Tolerance | Handles warm temperatures for hot water systems | Better than plastic; not as good as stainless steel |

Ease of Installation | Easy to put in; works with soldering, threading, and compression fittings | Easier than stainless steel; more ways to use than plastic |

Machinability | Easier to cut and shape into tricky designs | Easier to shape than stainless steel |

Thermal/Electrical Conductivity | Moves heat and electricity well | Better than stainless steel and plastic |

Cost-Effectiveness | Good price for most uses | Cheaper than stainless steel |

Brass valves look nice, work well, and can be used in many ways. These things make them a top pick for plumbing and HVAC jobs.

Brass valve features help make plumbing, HVAC, and factory systems work well. These features show how strong a valve is and how long it will last. They also help people pick the right valve for stopping leaks and keeping things safe.

Durability is a very important feature of brass valves. Brass valves do not break easily when used every day. This is why people use them at home and in factories. A brass globe valve in a house can last more than 20 years. In factories, it lasts about 5 to 10 years because the work is harder. Brass ball valves in homes can last 20 to 30 years. In factories, they last 10 to 15 years.

Valve Type | Application Type | Average Lifespan (Years) | Notes |

|---|---|---|---|

Brass Globe Valve | Residential | 20+ | Mild conditions, low pressure, clean water |

Brass Globe Valve | Industrial | 5-10 | Harsh conditions, high pressure, corrosive |

Brass Ball Valve | Residential | 20-30 | Typical lifespan in home plumbing systems |

Brass Ball Valve | Industrial | 10-15 | Depends on environment and maintenance |

Brass valves work best where there is not much rust, low pressure, and not too much heat. Stainless steel valves are better for really tough jobs. But brass valves cost less and are easier to join together. For most plumbing and HVAC jobs, brass valves last long and save money.

Brass valves last longer than plastic or aluminum ones.

The soft seals inside can wear out before the brass does.

Brass adapter fittings and quick connect couplings help make systems stronger.

Corrosion resistance is another big feature of brass valves. Brass does not rust or get damaged by chemicals because it is made from copper and zinc. This helps stop leaks and cracks, so you do not need to fix or change them often. Studies show brass ball valves stay strong in water and do not get holes or cracks. Corrosion resistance also keeps water clean, which is important for food and medicine.

Brass valves do not need much care. Just clean and check them sometimes. Their corrosion resistance helps stop leaks, which is very important for gas systems.

Brass valves can handle salty, sour, and very hot or cold places. This helps them control flow and stop leaks in many jobs.

Temperature tolerance is important for brass valves in hot water and HVAC systems. Most brass globe valves work safely from -20°C to 200°C (-4°F to 392°F). Good brass ball valves with PTFE or Viton seals can go up to 180°C (356°F). Some special brass valves can take even more heat.

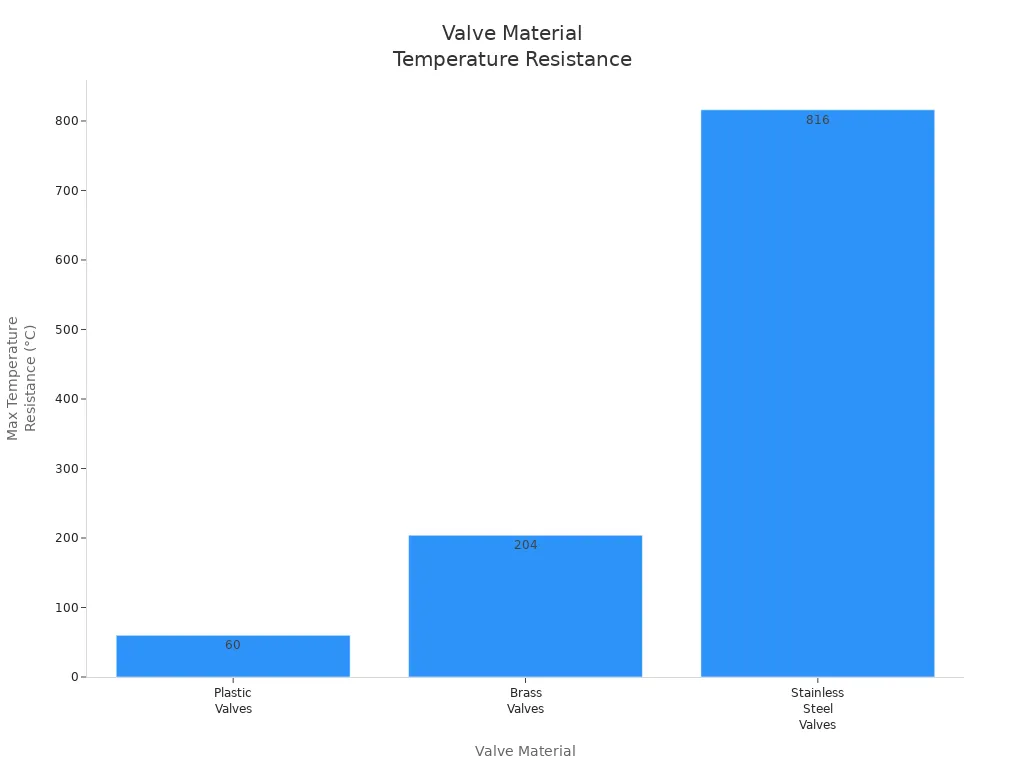

Valve Material | Temperature Resistance Range |

|---|---|

Plastic Valves | Up to 140°F (60°C) |

Brass Valves | Up to 400°F (204°C) |

Stainless Steel Valves | Up to 1500°F (816°C) |

Brass valves keep their shape and strength in warm and hot places. This makes them good for hard jobs in factories. Their temperature tolerance helps them work well in hot water, HVAC, and pipes. But for very hot jobs, stainless steel valves are better.

Malleability is a special feature of brass valves. It means brass is easy to shape and cut. Brass is easier to work with than bronze or stainless steel. Makers use brass to make tricky valve parts, quick connect couplings, and brass adapter fittings. If brass has more copper, it is softer and easier to shape.

Brass can be rolled, drawn, stamped, forged, or pushed into shape. This lets makers create valves in many shapes. This helps stop leaks and makes strong parts. Malleability also lets brass valves fit into small or odd spaces without breaking. This is helpful for plumbing and HVAC jobs.

Brass valves are easier to shape than bronze ones.

Free machining brass (Alloy 360) is best for making exact valve parts.

Malleability helps brass valves stay tough after shaping.

Brass valve features like durability, corrosion resistance, temperature tolerance, and malleability make them a great choice for stopping leaks and controlling flow. People get valves that work well, cost less to fix, and are easy to put in.

There are many main types of brass valves. Each type does a special job to control flow. The most common types are:

Brass ball valve: This valve has a ball with a hole inside. The handle turns the ball to open or close the flow. It shuts off fast and is strong. People use it at home and in factories because it seals well.

Brass check valves: These let liquid move in just one direction. They close by themselves using a spring or gravity. This keeps dirty water from going back into clean pipes.

Brass gate valve: This valve has a gate that slides up and down. It starts or stops the flow. People use it in water pipes that stay open or closed for a long time.

Brass globe valve: This valve has a plug that moves up and down. It lets you control how much liquid goes through. It is good when you need to change the flow very carefully.

Brass angle valve: This valve turns the flow by 90 degrees. It is often put behind sinks or toilets. It makes it easy to turn water off for repairs.

Brass stop valve: This valve shuts off water to one spot, like a sink. It comes in straight or angled shapes. This helps it fit in different places.

Two-way and three-way valves: These valves move flow between more than one pipe. People use them in heating, cooling, and watering systems.

Tip: Some brass valves, like quick connect couplings and brass adapter fittings, are easy to put in. They help stop leaks and make systems stronger.

Valve Type | Main Function | Typical Use Case |

|---|---|---|

Brass ball valve | Fast shut-off/on | Plumbing, HVAC, industry |

Brass check valves | Stop backflow | Water, gas, oil lines |

Brass gate valve | Start or stop flow | Water supply, irrigation |

Brass globe valve | Control flow amount | Heating, chemical work |

Brass angle valve | Change flow direction | Fixtures, appliances |

Brass stop valve | Shut off fixtures | Sinks, toilets |

Brass valves are used in many places like homes, businesses, and factories. At home, people use brass ball valve and brass gate valve types the most. They control water pipes, turn off water to sinks, and stop leaks. Brass check valves keep water safe by stopping dirty water from going backward.

In heating and cooling, brass valves control water and air. They also help with refrigerant and protect machines from too much pressure. Brass ball valve and brass check valves are important for quick shut-off and steady flow. Brass angle valve and brass stop valve types make fixing things behind appliances easier.

Factories use brass valves because they are strong and do not rust easily. They use brass check valves and brass ball valve products in oil, gas, and food factories. These valves can handle high pressure and big temperature changes. They help keep work safe and running well. Cars and boats use brass valves to control fuel, oil, and coolant. This helps engines work better and stay safe.

Note: Brass valves help save time and money on repairs. They seal well and are easy to use. Their rust resistance makes them good for tough jobs.

Brass valves, like two-way and three-way valves, are also used in watering, cleaning water, and energy systems. They last a long time and work in many jobs. Other products, such as air connector quick couplings and ACR copper fittings, help brass valves work in special systems.

Brass valves are tough and do not rust easily. They help control water or gas flow very well. This makes them good for plumbing, heating, and factory systems. Their seals are strong and simple to use. This helps stop leaks and keeps things working for a long time. It is important to know about pressure ratings, temperature limits, and material quality. These things help people pick the right valve for their system. When choosing a valve, think about what the job needs and how it connects. You should also look at quick connect couplings or brass adapter fittings. Picking the right valve keeps things safe, saves money, and helps the system work better.

Brass valves do not rust and can handle hot or cold. They work with water, gas, and cooling liquids. Quick connect couplings and brass adapter fittings help stop leaks in plumbing and HVAC jobs.

Most brass valves work for 20 to 30 years at home. How long they last depends on water and care. Brass ball valves and globe valves give good results for many years.

Yes, brass valves fit well with ACR copper fittings. This helps air conditioning and cooling systems work right. Installers like them because they fit together and seal tightly.

Brass valves follow rules for safe drinking water. Lead-free brass keeps water clean. Companies like Ningbo Tophcool Metal Fittings make safe products for water systems.

A brass ball valve has a ball that turns to shut off fast. A brass gate valve has a gate that slides to control flow slowly. Ball valves are good for quick shut-off. Gate valves are better for steady flow.